| ethylenediaminetetraacetic acid (EDTA) |

Sunday, December 28, 2014

EDTA

A chelating agent of particular economic significance is ethylenediaminetetraacetic acid (EDTA).

EDTA is a versatile chelating agent. It can form four or six bonds with a metal ion, and it forms chelates with

both transition-metal ions and main-group ions. EDTA is frequently used in soaps and detergents, because it

forms a complexes with calcium and magnesium ions. These ions are in hard water and interfere with the

cleaning action of soaps and detergents. The EDTA binds to them, sequestering them and preventing their

interference. In the calcium complex, [Ca(EDTA)]2–, EDTA is a tetradentate ligand, and chelation involves

the two nitrogen atoms and two oxygen atoms in separate carboxyl (-COO–) groups. EDTA is also used

extensively as a stabilizing agent in the food industry. Food spoilage is often promoted by naturally-occurring

enzymes that contain transition-metal ions. These enzymes catalyze the chemical reactions that occur during

spoilage. EDTA deactivates these enzymes by removing the metal ions from them and forming stable chelates

with them. It promotes color retention in dried bananas, beans, chick peas, canned clams, pecan pie filling,

frozen potatoes, and canned shrimp. It improves flavor retention in canned carbonated beverages, salad

dressings, mayonnaise, margarine, and sauces. It inhibits rancidity in salad dressings, mayonnaise, sauces, and

sandwich spreads. EDTA salts are used in foods at levels ranging from 33 to 800 ppm.

Wednesday, June 4, 2014

Tuesday, March 25, 2014

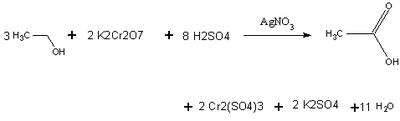

Breathalyzer

Chemistry of a Breathalyzer

Using Beer's law, the spectrophotometer can relate concentration to absorbance levels of the chromium ion. The amount of alcohol present is proportional to the stoichiometric coefficients. An actual breathalyzer only needs to detect 25 micrograms of ethanol to give a reading 0.10 Blood Alcohol Level.

Credit : http://chem242.blogspot.com/2005/08/chemistry-of-breathalyzer.html

Sunday, March 23, 2014

Saturday, March 22, 2014

Monday, February 24, 2014

Expanded PS

Polystyrene Boxes for Food

Concerns

over the use of PS should best be analysed based on facts rather than on

perception .

The fact

that advanced countries like Japan , US and The EU continue to allow the use of

PS as a food packaging material speaks volume about its safety .

Basically there are 2 forms of PS foam

·

Extruded polystyrene [ foam plates , egg cartons and other food food service applications ]

·

Expanded polysterene [ coffee

cups , packaging of delicate E & E appliances

, consumer products ]

Both

types are also used as thermal insulation in Industrial , commercial and

residential construction.

[i]What is EPS?

EPS (Expanded Polystyrene) or as many know by The Dow Chemical Company's

trade marked name, STYROFOAM,

is an extremely lightweight product that is made of expanded polystyrene beads.

Originally discovered by Eduard Simon in 1839 in Germany by accident, EPS foam

is more than 95% air and only about 5% plastic.

Small solid plastic particles of polystyrene are made from the monomer

styrene. Polystyrene is normally a solid thermoplastic at room temperature that can be melted at

higher temperature and re-solidified for desired applications. The expanded

version of polystyrene is about forty times the volume of the original

polystyrene granule.

Expanded polystyrene (EPS) is a

versatile, lightweight material that can be manufactured into a variety of

products. EPS offers a high-performance

yet economical support for a wide variety of items—from sensitive

electronics to appliances to pharmaceuticals—to be safely delivered to market.

Manufacturers rely on EPS packaging because of its ability to prevent or minimize product damage during

transit and its excellent insulation properties required for food and

medical shipments.

Yet

EPS packaging, just like any disposable packaging, will eventually become a solid waste and have to be managed. But here’s the good news: EPS

is recyclable. Although the availability of polystyrene recycling programs

varies by community and can be limited, the EPS industry uses average of 50

percent of the post consumer material collected in the manufacture of new EPS

transport packaging and loose fill packaging, which has reduced requirements

for raw material resources, energy consumption has diverted material from landfills.

Yet

EPS packaging, just like any disposable packaging, will eventually become a solid waste and have to be managed. But here’s the good news: EPS

is recyclable. Although the availability of polystyrene recycling programs

varies by community and can be limited, the EPS industry uses average of 50

percent of the post consumer material collected in the manufacture of new EPS

transport packaging and loose fill packaging, which has reduced requirements

for raw material resources, energy consumption has diverted material from landfills.

Subscribe to:

Comments (Atom)